|

1:20 SCALE - RADIO CONTROLLED MODEL: ELIZABETH SWANN

Dig for gold with our A - Z or set sail for HOME

|

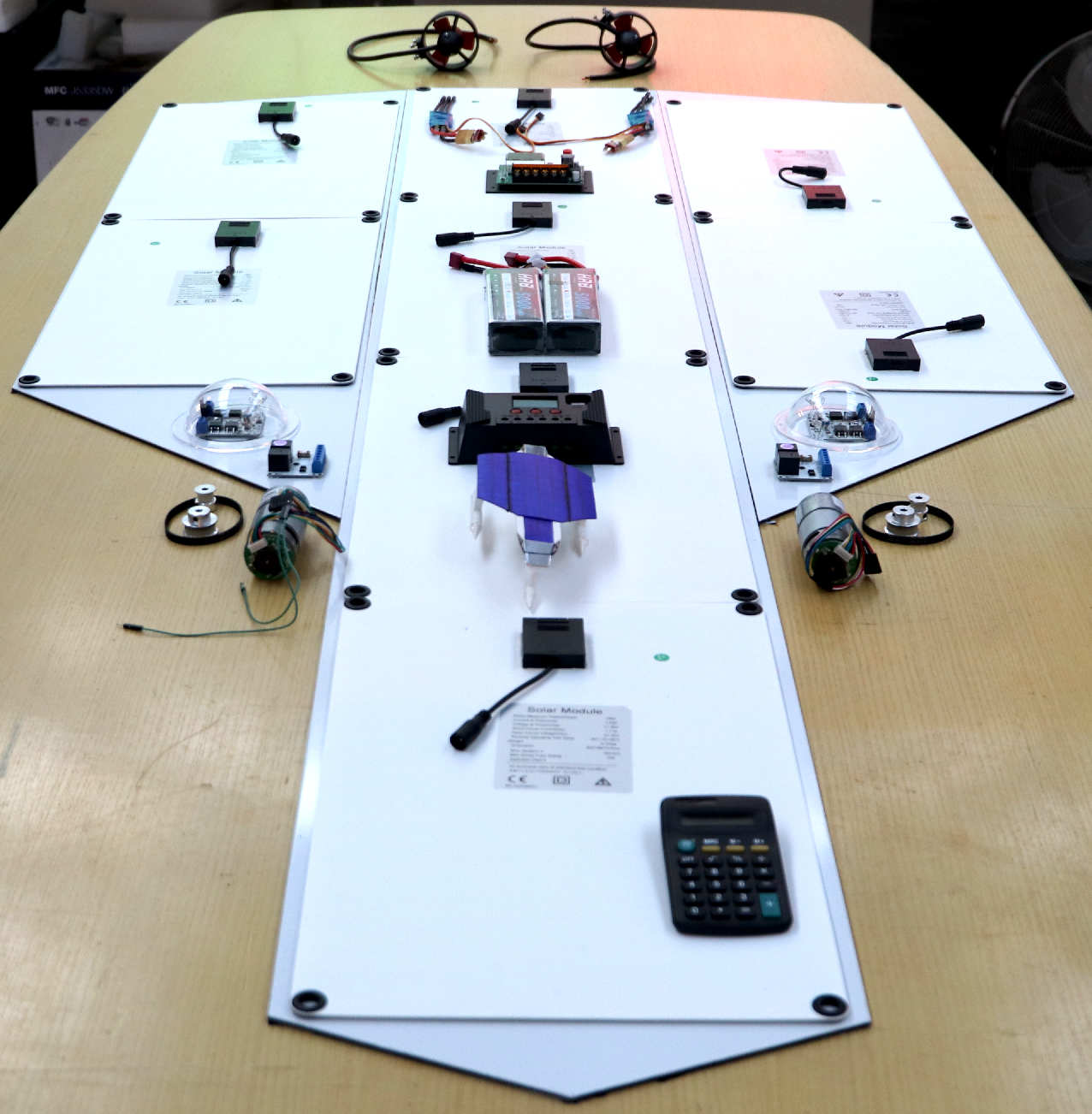

These are some of the main components of the 1:20 scale Elizabeth Swan technology demonstrator. We applied for part funding for this project from the Dti's TRIG marine technology competition. But, they said they were concerned about cleaning of the panels of salt caking at sea, as applied to ships. We have solved that problem, and were prepared to share that information in return for helping us with development costs. We considered the automatic furling and sun tracking to be an important feature for applications like cargo ships, cruise liners and ferries - not so the UK government. But then, we suppose that most governments around the world are in a pickle. Looking for ways to power ships to meet with the IMO's zero targets for 2100 without much modification of hulls and decks. The target for 2030 is a 40% reduction in GHG emissions. The Elizabeth Swann is a clean-sheet-of-paper design. Not flavour of the month with fleet operators, as well we appreciate. But then progress is sometimes financially painful. In the commercial world it is all about profits. Now, the planet gets a look in, but still has to wait for existing ships to depreciate. We have suggested a scrappage scheme is applied to induce ship operators to change out hulls earlier, as was applied to cars some years ago.

FEBRUARY 2024 - Further hull development took place in 2023 to improve performance, to allow the taking of two Guinness World Records with one vessel, necessitating an increase the diameter of the original jig base and tower locators - mainly to accommodate off the shelf components - rather than be forced to manufacture bespoke electronics. We thus calculated the need for larger hull tubes, now being installed in March 2024, the equivalent of laying a keel. Fortunately, the wooden jig was easy to adapt, since many man hours were invested in the tower design and joinery. We did not want to start all over again, unless absolutely necessary. As you can see, the spruce and plywood frame on which the solar panels are mounted, fitted like a glove, when re-installed. Now, the forming of alloy ends and foils can continue. Followed by fitting of the solar wings, drives and sun tracking electronics. It will be a miniature of the real control system. The Swann can set the 1st hydrogen record, and beat the existing solar record.

|

|

APRIL 24TH - Leo is seen here offering up an aluminium fold, to check for length in relation to the deck, which is covered in solar panels. Leo is interested in boat design and practical metal working skills. In the background you can see a solar catamaran design that was tested a long time ago, in the development of the present trimaran design. We are hoping to have this model ready for another local United Nations event in November. So, we have our work cut out.

It is very important to measure carefully. We work to a tolerance of around 0.25mm. But in practice, where there are folds, 0.5mm is usually acceptable with a little fettling at the joins. In the background you can see a SWATH design that was tested well before the Elizabeth Swann design hit the drawing board. The submerged twin hull concept proved to have a higher drag than expected, and it was difficult to trim. The radio controlled model had four tanks that could be flooded or pumped out, for trim and ride height adjustment for different sea conditions.

|

|

|

THE MAIN COMPONENTS OF THE ELIZABETH SWANN TRIMARAN

Superstructure. This frame, helms and cabins, provides a structure to attach the solar wings, camera, lights, and other components of our model. On the full size vessel, much of the superstructure will be in 5083 marine grade alloy.

Thrusters. The thrusters are electrically or hydraulically powered propellers used to maneuver the vehicle. There are almost always multiple thrusters to provide movement in multiple directions.

STERN - Where the prow on the Elizabeth Swann would carry the Cleopatra figurehead, the stern could be adorned with relief's and a mask in gold and Egyptian blue enamel, the artwork for which could be something like, or based on that above. Click on the picture above to see how the Queen of the Nile's figurehead was developed from a 280 millimeter study to a 2.8 meter sculpture.

Solar Wings. As this model is powered with free energy from nature, it is autonomous, not needing shore based charging, or fossil fuels. Moveable wings allow the solar panels to change position to face the sun, so harvesting more free energy than a ship with fixed deck panels. In addition, having wings that fold, makes the model, and full size ship, safer in stormy conditions. Testing in winds will be one of the group of experiments, in a specially equipped test tank.

Pilot Controls. The surface controls can range from something that looks like the control room for a spaceship to something as simple as a

smartphone, or an Xbox game controller. The surface controls provide a physical interface for the pilot to control the vehicle and a display of feedback from the vehicle including the camera view.

|

|

Dig for treasure with our A - Z or set a course for HOME shipmates

This website is Copyright © 2023 Cleaner Ocean Foundation. The rights of Cleaner Ocean Foundation to be identified as the author of these works have been asserted in accordance with section 77 and 78 of the Copyright Designs and Patents Act 1988. This website and the associated Elizabeth Swann artwork and designs are Copyright © 2024 Cleaner Ocean Foundation.

|