|

IMO - INTERIM RECOMMENDATIONS FOR CARRIAGE OF LH2

Please use our A-Z INDEX to navigate this site or return HOME

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ANNEX 18

RECOGNIZING a need for the development of the Interim Recommendations for carriage of liquefied hydrogen in bulk, ACKNOWLEDGING that, in the interim, there is an urgent need to provide recommendations to the Administrations on safe carriage of liquefied hydrogen in bulk, ACKNOWLEDGING FURTHER that the Interim Recommendations are intended to facilitate establishment of a tripartite agreement for a pilot ship, which will be developed for the research and demonstration of safe long-distance overseas carriage of liquefied hydrogen in bulk, HAVING CONSIDERED the Interim Recommendations prepared by the Sub-Committee on Carriage of Cargoes and Containers at its third session,

1 ADOPTS the Interim Recommendations for carriage of liquefied hydrogen in bulk, the text of which is set out in the annex to the present resolution;

2 INVITES Member States to apply the Interim Recommendations to the pilot ship carrying liquefied hydrogen in bulk taking the explanatory notes into consideration;

3 AGREES to acquire information on safe carriage of liquefied hydrogen in bulk prior to amendment to the IGC Code for the inclusion of liquefied hydrogen;

4 AGREES further that these Interim Recommendations may need to be reviewed if they are to be applied to ships other than the pilot ship; and

5 URGES Member States and the industry to submit information, observations,

comments and recommendations based on the practical experience gained through

the application of the Interim Recommendations and submit relevant safety analysis on ships

carrying liquefied hydrogen in bulk.

3 EXPLANATION ON GENERAL REQUIREMENTS

Remarks:

* At their normal boiling points for comparison purpose. ** At normal temperature and pressure. *** Ignition and combustion properties for air mixtures at 25°C and 101.3 kPaA. **** Normal Hydrogen.

3.2 Explanation on respective requirements 3.2.1 Ship type (column 'c')

3.2.1.1 As a result of the studies, the following points were noted in relation to ship type allocated in the Code: .1 type 1G is allocated only to dangerous goods of class 2.3* in the International Maritime Dangerous Goods Code, but not to class 2.2 and class 2.1; .2 type 2G and type 2PG are allocated mainly to non-toxic flammable gases of class 2.1; and .3 type 3G is allocated only to non-flammable and non-toxic gases of class 2.2. 3.2.1.2 "Type 2PG" is not applicable to liquefied hydrogen for the reason that the design temperature is lower than -55°C. Taking into account that liquefied hydrogen is a class 2.1 dangerous good, it is appropriate to allocate "type 2G" to liquefied hydrogen.

3.2.2 Independent tank type C required (column 'd') Independent tank type C is allocated only to dangerous goods of class 2.3 whose vapour density is heavier than air. Independent tank type C is considered not to be required for liquefied hydrogen.

3.2.3 Control of vapour space within cargo tank (column 'e') Special environment controls such as drying and inerting are generally required for liquid chemical products in consideration of the reactivity of cargo vapour and air. As is the case for LNG, it is considered not to be necessary to apply such requirements for liquefied hydrogen.

3.2.4 Vapour detection (column 'f') Because hydrogen is flammable and non-toxic, it is appropriate to require Flammable (F) as vapour detection for liquefied hydrogen.

3.2.5 Gauging (column 'g') On the grounds that Closed (C) gauging is required, in principle, for flammable or toxic cargoes, such as methane, it is considered to be appropriate to require Closed (C) gauging for hydrogen, taking into account that hydrogen has high ignitability and a wide flammable range in air and that closed gauging is effective to prevent leakage of gases into air.

4 SPECIAL REQUIREMENTS AGAINST HAZARDS OF LIQUEFIED HYDROGEN

4.1 Hazards of liquefied hydrogen to be considered

4.1.1 The hazards related to liquefied hydrogen are low ignition energy, a wide range of flammability limits, low visibility of flames in case of fire, high flame velocity which may lead to the detonation with shockwave, low temperature and liquefaction/solidification of inert gas and constituents of air which may result in an oxygen-enriched atmosphere, high permeability, low viscosity, and hydrogen embrittlement including weld metals. Where vacuum insulation is adopted, due consideration should be given to the possibility of untimely deterioration of insulation properties at the envisaged carriage temperatures of liquid hydrogen. The vacuum insulation evaluation should be specified for the normal range or upper limit of cold vacuum pressure (CVP), and loss of vacuum should be defined with respect to this value. Accordingly, effect of vacuum pressure should be taken into account at the time of design and testing of cargo containment systems and piping. Supporting structure and adjacent hull structure should be designed taking into account the cooling owing to loss of vacuum insulation.

4.2.2 Measures for condensed air

"Material of construction and ancillary equipment such as insulation shall be resistant to the effect of high oxygen concentrations caused by condensation and enrichment at the low temperatures attained in parts of the cargo system. Due consideration shall be given to ventilation in such areas where condensation might occur to avoid the stratification of oxygen-enriched atmosphere."

A similar special requirement is applicable to hydrogen.

4.2.3 Removal of impure substances condensed

The removal of impure substances, such as those contained in condensate in pipes, should be separately considered. Installation of filters can be an appropriate measure and should be stipulated as a special requirement.

4.2.4 Prevention of blockage due to formation of water or ice Pressure relief systems may become blocked due to formation of water or ice, depending on the temperature and humidity of air, resulting from the low temperature of the cargo and its vapour (see paragraph 4.2.2). Appropriate means should be provided to prevent such phenomena.

4.3 Hydrogen embrittlement

4.3.1 Selection of appropriate materials should be required to prevent failures owing to

hydrogen embrittlement. The publication by AIAA2) introduces some appropriate materials

resistant to hydrogen embrittlement, and concludes that aluminium is the material least

affected. 4.3.2 International or national standards should be followed for the selection of materials for the design of liquefied and gaseous hydrogen installations in a marine environment.

4.4.1 Prevention of leakage from cargo tanks

To mitigate leakage of hydrogen, it is deemed appropriate to require "butt weld full penetration" type welds, regardless of tank types, taking into account the high permeability of hydrogen. Furthermore, dome-to-shell connections welds and nozzle welds should be designed with full penetration regardless of tank types, taking into account paragraphs 4.20.1.1 and 4.20.1.2 of the Code.

4.4.2 Prevention of leakage from pipes

To mitigate undetected accumulation of hydrogen in a confined space, effective measures should be employed to reduce the possibility of leakage of hydrogen, taking its high permeability into account. Effective measures can be double tube structures, or fixed hydrogen leak detectors in areas assessed as being highly hazardous with regard to hydrogen leakage. Hydrogen leakage through welds, joints and seals is an important consideration for the design of hydrogen systems and an important operational issue.

4.4.3 Implementation of effective tightness test

4.4.3.1 Tightness tests for cargo tanks and cargo pipes/valves are required by

paragraphs 4.20.3.2, 5.13.1 and 5.13.2.3 in the Code respectively. Helium or a mixture of 5% hydrogen and 95% nitrogen should be used as the medium for tightness tests, instead of air, because the permeability of hydrogen is high.

4.4.4 Confirmation of appropriate operating procedure Instructions/manuals containing the operating procedures for the prevention of leakage during transport, methods for early detection in case of leakage, and appropriate measures after such events, should be provided.

For this, paragraph 18.3 of the Code requires that the information shall be on board and available to all concerned, giving the necessary data for the safe carriage of cargo. In detail, the Code requires such information on action to be taken in the event of spills or leak, countermeasures against accidental personal contact, procedures for cargo transfer, and emergency procedures to be on board. With regard to the manuals on procedures for liquefied hydrogen during carriage and transfer operations, the requirements in the Code are applicable and no special requirement is necessary.

4.5 Low density and high diffusivity Though low density and high diffusivity of hydrogen may reduce the possibility of formation of a flammable atmosphere in open spaces, adequate ventilation is necessary for enclosed spaces in cargo areas where formation of hydrogen-oxygen/air mixture may occur. Paragraph 12.2 of the Code requires fixed ventilation systems or portable mechanical ventilation for such enclosed spaces. These requirements in the Code are applicable to liquefied hydrogen carriers and no special requirement is necessary in this regard.

4.6 Ignitability

4.6.1 The Code requires electrical bonds of the piping and the cargo tanks in paragraph 5.7.4, exclusion of all sources of ignition in paragraph 11.1.2, electrical installations to minimize the risk of fire and explosion from flammable products in paragraph 10.2.1 and so on, in order to prevent ignition of flammable cargoes.

4.6.2 The Code requires compliance with the relevant standards issued by the International Electrotechnical Commission (IEC) and the IEC standards specify the details of such safety measures depending on the respective properties of flammable gases including hydrogen. No special requirement is necessary with regard to ignitability of hydrogen*.

4.7 Fire hazard 4.7.1 Safety of personnel in case of fire

To avoid the effects of flame and UV radiation produced by a hydrogen fire, it is effective to

use firefighter's outfits and protective equipment. The Code already requires

firefighter's outfits for ships carrying flammable products in paragraph 11.6.1 and safety equipment in

paragraph 14.3. This issue should be considered as the matter of cargo information required

by paragraph 18.3 of the Code. Due consideration should be given to the invisible nature of

hydrogen fire.

Dry chemical powder fire-extinguishing or carbon dioxide fire-extinguishing systems are considered to be effective in case of hydrogen fire and such fire-extinguishing systems are already required by paragraphs 11.4 and 11.5 of the Code. Special requirements for installation of other types of fire-extinguishing systems are considered unnecessary, except with regard to the increased of amount of carbon dioxide required, as mentioned in the next paragraph in this document.

4.7.3 Increase of the amount of gas for carbon dioxide fire-extinguishing systems

4.7.3.1 Paragraph 11.5.1 of the Code requires as follows: "Enclosed spaces meeting the criteria of cargo machinery spaces in 1.2.10, and the cargo motor room within the cargo area of any ship, shall be provided with a fixed fire-extinguishing system complying with the provisions of the FSS Code and taking into account the necessary concentrations/application rate required for extinguishing gas fires." 4.7.3.2 Chapter 5 of the FSS Code, i.e. Fixed gas fire-extinguishing systems, requires that the quantity of carbon dioxide for cargo spaces, unless otherwise provided, shall be sufficient to give a minimum volume of free gas equal to 30% of the gross volume of the largest cargo space to be protected in the ship, in paragraph 2.2.1.1.

4.7.3.3 On the other hand, NFPA 123) requires that the design quantity of carbon dioxide for hydrogen fire should be 75% or more of the gross volume of the protected space. The special requirement for an increased amount of carbon dioxide should be provided for carbon dioxide fire-extinguishing systems.

4.7.4 Features of hydrogen fire

Hydrogen burns at high temperature, but generally gives off less radiant heat than propane or other hydrocarbons (e.g. only about 10% of that radiated by an equal-sized propane flame). Although the heat radiated by a hydrogen flame is also relatively low compared to hydrocarbons, it is important to take into account the differences in heats of combustion, burning rate and flame size. Hydrogen flames are colourless or nearly colourless. Both of these characteristics make it more difficult to detect a hydrogen fire. Even relatively small hydrogen fires are very difficult to extinguish. The only reliable approach to extinguish a fire is to shut off the source of hydrogen supply.

4.8 High pressure hazard

4.8.1 High pressure is a hazard common to hydrogen and other flammable gases listed in

the Code. To prevent overpressure, the Code requires various measures such as pressure

control and pressure design. Specifically, paragraph 8.2, in regard to the provision of pressure

control of cargo tanks, requires fittings of pressure relief valves to the cargo tanks.

Furthermore, paragraph 7.1.1 requires temperature control by the use of mechanical refrigeration and/or design to withstand possible increases of temperature and pressure. In

addition, paragraph 15.2 specifies the filling limit of cargo tanks taking into account cargo

volume increase by its thermal expansion. These requirements are applicable for hydrogen

and no special requirement is considered necessary in this regard.

The wide flammability range makes disposal of cold hydrogen gas a major hazard. Cold plumes downwind and inadequate dilution to below 4% provide possibilities for flash-back to the vent from distant ignition sources outside safety-controlled areas. The low ignition energy and wide flammable range may present significant challenges.

4.11 Prevention of dangerous purging operation

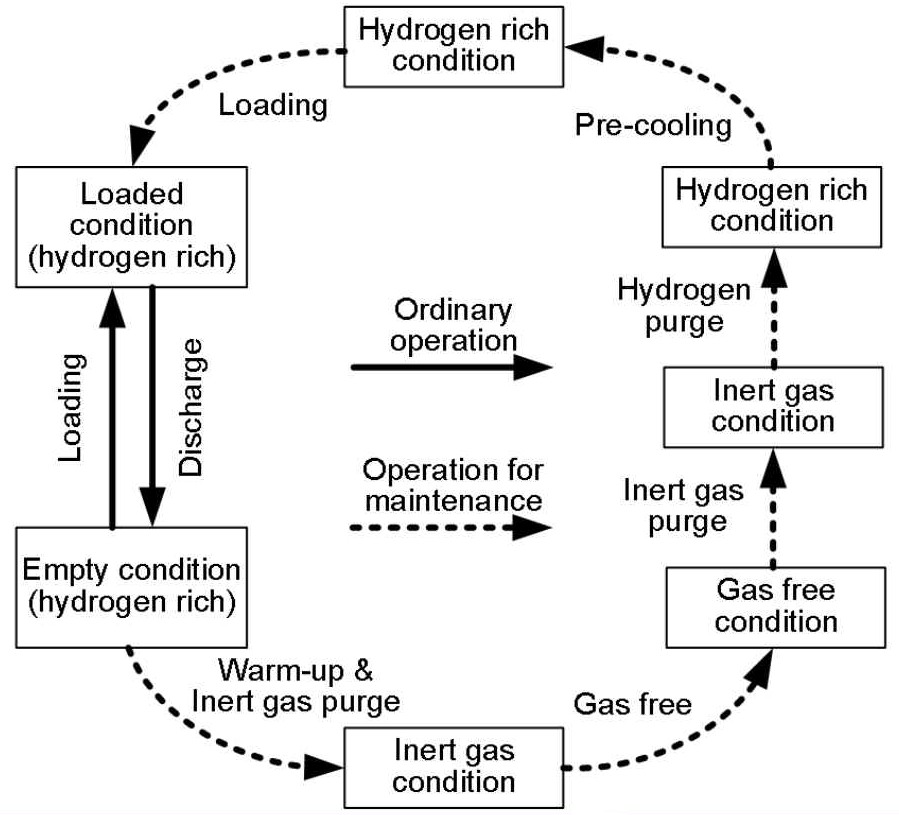

4.11.1 During cargo operations for maintenance, pipes and tanks should be purged with an inert gas or inert gases as illustrated in the figure below. For safety, due consideration should be given to temperature and boiling points of the inert gases. Residual pockets of hydrogen or the purge gas will remain in the enclosure if the purging rate, duration, or extent of mixing is too low. Therefore, reliable gas concentration measurements should be obtained at a number of different locations within the system for suitable purges. Temperature should also be measured at a number of locations. Oxidizing agents may exist in a hydrogen containing equipment, specifically: air, cold box atmospheres containing air diluted with nitrogen, or oxygen-enriched air that can be condensed on process pipe work within the cold box in special circumstances.

4.11.2 There are special measures that may need to be put in place in order to mitigate the hazards, e.g. air should be eliminated by nitrogen purge prior to introduction of hydrogen into cargo piping or processing equipment. Nitrogen should then be eliminated by hydrogen purge, where there is a possibility of its solidification in the subsequent process.

See also, International Code of the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk

REFERENCES

2) American Institute of Aeronautics and Astronautics, "Safety Standard for Hydrogen and Hydrogen Systems (Guide to Safety of Hydrogen and Hydrogen Systems)", 2005 (AIAA)

3) NFPA 12: Standard on Carbon Dioxide Extinguishing Systems 2005 Edition (NFPA)

4) IEC 60079-20-1 Ed. 1.0:2010 (b) Explosive atmospheres – Part 20-1: Material characteristics for gas and vapour classification – Test methods and data

5) UN Recommendations on the Transport of Dangerous Goods – Model Regulations, Nineteenth revised edition

6) NFPA 2: Hydrogen Technologies Code 2016 Edition (NFPA)

7) IEC/ISO 31010:2009 Risk management – Risk assessment techniques

8) Cryogenics Safety Manual – Fourth Edition (1998)

9) SAE ARP 5580-2001 "Recommended failure modes and effects analysis (FMEA) practices for non-automobile applications"

10) National Institute of Standards and Technology (NIST) RefProp database

STANDARD ISO - 20m3 cryogenic tanks, multi-layered vacuum insulation, in stainless steel. Large tanks are available from many manufacturers concerning LNG.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ZEWT ALORS - The solar and wind powered 'Elizabeth Swann' will feature solar collectors energy harvesting apparatus. Her hull configuration is ideal to incorporate mass hydrogen storage tanks, offering ranges of up to 4,000nm on compressed gas, or an extended range on liquid hydrogen tanks (optionally) as a drop in cartridge, or safety module.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A-Z

INDEX OF H2 POWERED FUEL

CELL SHIPS

LIQUID HYDROGEN LINKS & REFERENCE

https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MSCResolutions/MSC.420(97).pdf

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Please use our A-Z INDEX to navigate this site or return HOME

This website is Copyright © 2021 Jameson Hunter Ltd

|