|

WEIGHT ANALYSIS - DISPLACEMENT (V1.1 [2021])

Please use our A-Z INDEX to navigate this site or return HOME

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DESIGN WEIGHT - It's very different working in paper and cardboard, compared to marine alloys. We should also consider that our model tests will mostly be conducted in fresh water which is 1 kg/liter as opposed to 1.025 kg/liter for seawater - meaning that the full size vessel will have that advantage also, unless that is the operators intend navigating mainly in rivers.

One of the most important considerations during the design stage is the mass of the hull, hence the displacement in water. The weight of the hull dictates the power required to drive a ship from one destination to another. That, and the design of the hull. Which includes the design of the superstructure, hence air and water drag. The air drag element often being overlooked. Especially in sailing boats, where the air drag, or sails, is used to drive the vessel.

Since this page was posted in 2021, the vessel has grown. See 2023 V2 weight analysis.

As you can see from the estimations below, the bulk of the vessel is the aluminium used to fabricate the hull and the energy storage batteries. Of these two items, we can alter the mass of the batteries significantly, once we know the safe operating parameters from trials in the Atlantic. Defining a formula for solar and wind powered ships is one of the main objectives.

People often ask for the formula before the experiments have been undertaken to furnish such rules. That is putting the cart before the horse, but then we have to start somewhere. For the sake of safety, we have allowed a 3 day reserve at a reasonable operating speed. If we already knew what to specify, we'd not need to build the Swann. To quote Albert Einstein, a person who was frequently asked if he knew what he was doing: "If we knew what we were doing it would not be called research."

With this project we have 3 stages of development, all interactive with the other:

1. We have first to design a ship in principle. 2. Test the hull configuration in small scale tests in a towing or other tank, called a water basin. 3. Only then might we proceed to building the full size yacht.

1:20

MODEL SHIP TARGET WEIGHTS (tank

tests)

Weight estimates for the model are not so critical, but when it comes to cutting metal full size, mistakes can be costly. Hence, working in scale for all design conceptualizing. The value in constructing a small scale model is not limited to just tank testing. Potential design issues are frequently encountered, giving the project managers useful advance information of obstacles to be overcome.

FULL SIZE SHIP TARGET WEIGHTS

HULL DRAG - The weight of the hull determines our hull drag - dependent on many variables, such as conversion efficiency. You can see from energy estimates graph, that to reach our 10 knot goal, we need around 27kW of continuous energy across the Atlantic, for which we'd need ideal conditions. A more easily achieved target would be 7.5 knots, requiring 14.5kW continuous. While the present record of 5.3 knots, held by PlanetSolar, could be equaled with just 7.5kW of energy from the sun, if our mass is 36,300kg, for our wave piercing trimaran design.

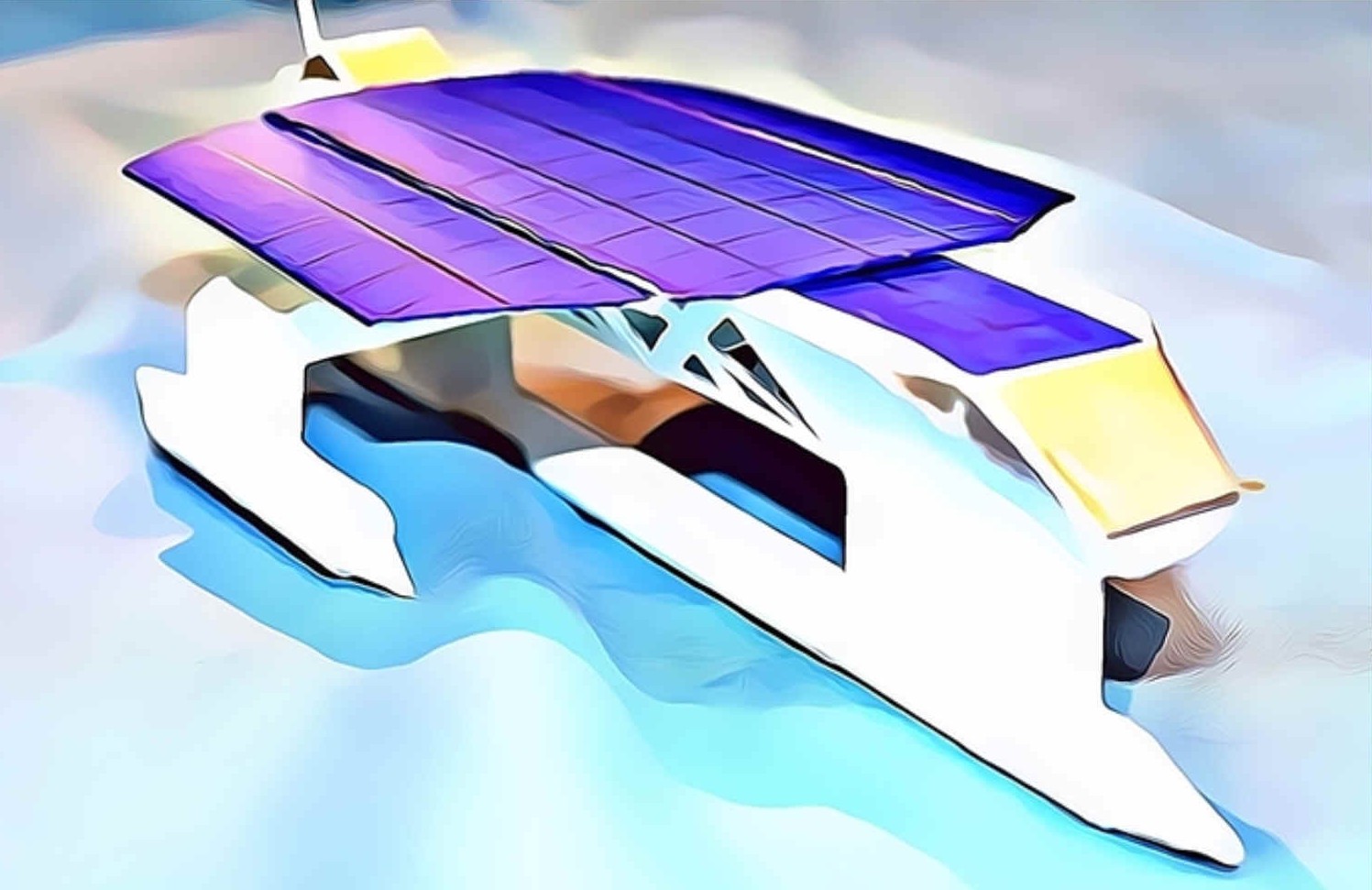

2. A single central wave piercing hull stabilized by outriggers as a trimaran including:

a) Ultra light superstructure purposed designed to harvest energy from nature via b) and c) below,

b) Solar wings that track the sun and fold for storms, in concert with

c) A turbine generator on a mast that tracks wind conditions and furls for storms.

The theoretical displacement we are working towards is: 30,000 - 45,000 kilograms (target) in 5083 marine grade alloy.

SHIP BUILDING MATERIALS

Steel

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Please use our A-Z INDEX to navigate this site or return HOME

This website is Copyright © 2021 Jameson Hunter Ltd

|