|

PROPULSION - PROPELLERS Vs THRUSTERS

Please use our A-Z INDEX to navigate this site or return HOME

|

|||

SILENCE IS GOLDEN - Solar powered yachting takes another small step for mankind, but, a giant leap for zero emission boating, with the development of these superbly engineered units from Italy. The patented technology underpinning these superb hydro-jets puts them at the top in terms of efficiency and overall performance. They achieve superior thrust, vibration free in absolute silence when fitted as per specification. The Elizabeth Swann will be using these motors by special arrangement with Sealance.

Having decided on the hull configuration and energy harvesting apparatus, we need to look at ways of improving the conversion rate of the stored electricity to propulsive thrust. You'd be surprised just how inefficient and noisy many propellers are.

Consider a small boat powered by an I.C. outboard engine where small diameter props are used at high revolutions via a gear box and drive train. When these factors are combined, it isn't surprising that motors of 20 hp or more are often fitted to quite small boats, that had they been multi-hulls and electric, about 5hp is all that is needed.

Another way of looking at it, is that with a propeller efficiency of a trolling motor of 50%, then it's actually producing 0.49 kW or 2/3 hp to generate around 55lbf (55lbs thrust). 1kW = about 110lbs thrust @ 50% efficiency.

We

have allowed approximately twice what we need (based on archive

estimates) for the dream of attaining 10 knots

performance, to cater for any increase in size of the hull as it

develops, and poor weather performance. We can shave that down as the

design is perfected. Or, we can keep that extra performance in our back

pocket. This is just a starting point, because we will not know how

efficient our energy harvesting arrangement is, until it is tried.

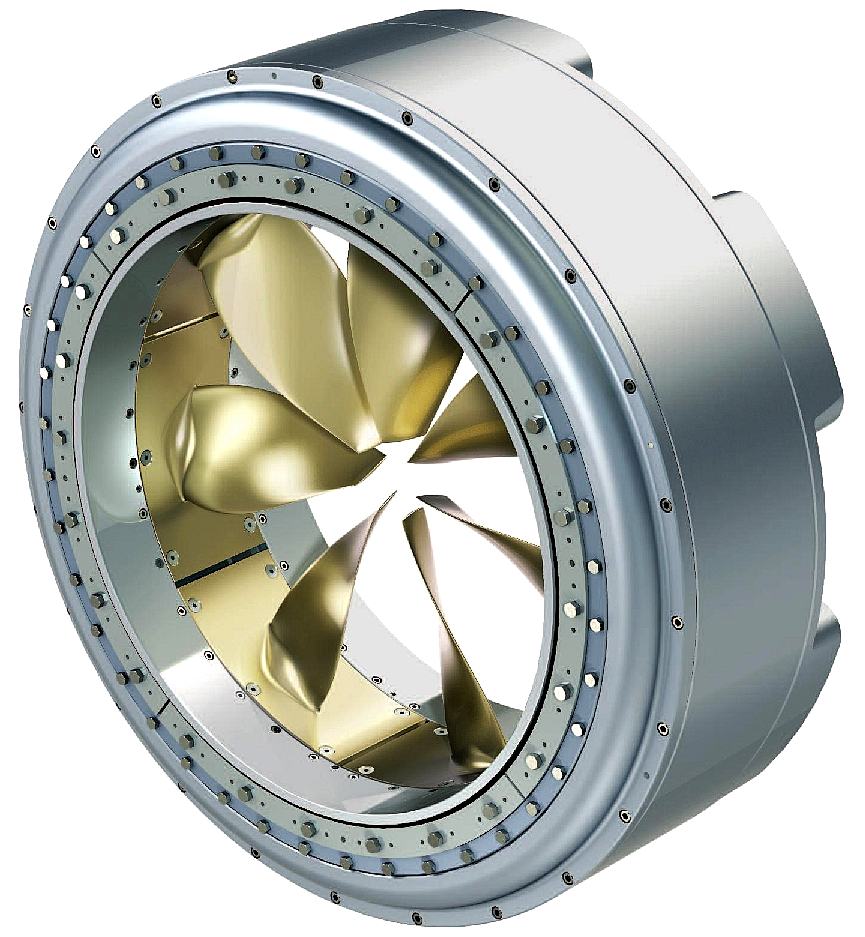

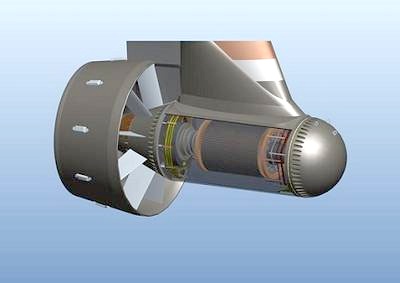

AZIMUTH PODS - Rim drive propellers are now a popular alternative for underwater applications, such as deep sea submersibles. They are also becoming attractive for surface vessels. The Schottel SRT [left] is an electric propulsion system with no gearbox or drive shaft. The electric motor stator is in the body of the drive with the (replaceable) propeller blades attached to the inside of the rotor. This saves weight, shaft and gearbox complications to reduce noise and cavitation. The electric motor is permanently cooled by the surrounding water and water lubricated plain bearings are accessible for maintenance work.

THRUSTERS - Two more designs for thrusters. The Sealence Deep-Speed on the right has a large diameter armature and a nice pod designed as an easy to install package, including controllers and batteries as required. Having the stator and rotor outside the propeller (impeller) blades offers greater torque potential, than a smaller rotor as in the more conventional electric motor on the left. We very much like the Deep Speed specifications.

An electric drive train can improve the conversion of energy to propulsive force, where synchronous dc machines are now very efficient at higher voltages. Propeller design is very important, but is often overlooked, where large diameter, thin, twin-blades revolving at low rpm are more efficient than small diameter triple blades, but may not be practical for commercial ships that cannot achieve the thrust in relations to tonnage and still enter ports with draught limitations.

In the quest for more efficient marine propulsion, free flow propellers have been shrouded and ducted as impellors for jet drives, typically powered by diesel engines. The 'Kort' style shrouding with or without stator blades, improves static thrust by around 10%, whereas hydrojets or jet-pumps are only really useful for higher speed vehicles and remain expensive.

The latest electric, (azimuthal-pod) shaft-less rim drives, or jet thrusters, potentially offer even more efficiency by cutting out shafts, bearings, seals and couplings - being water lubricated sometimes with magnetic bearings, and direct acting blades attached to the motor/rotor. Other advantages are easier mounting and freedom to locate almost anywhere. They can also be the rudder if arranged to rotate for steering, and so replace bow thrusters at one end of a vessel.

KNOTS Vs kW - A hull drag curve is dependent on many variables, such as conversion efficiency. You can see from the above graph (assuming 70% prop efficiency), that to reach our 10 knot goal, we need around 27kW of continuous energy across the Atlantic, for which we'd have to have ideal conditions. A more easily achieved target would be 7.5 knots, requiring 14.5kW continuous. While the present record of 5.3 knots, held by PlanetSolar, could be equaled with just 7.5kW of energy, even though the Swiss boat generates more solar energy than the Swann - that hull drag is lower from the reduced frontal area and improved power to weight ratio.

DRAFT SPECIFICATIONS

The Elizabeth Swann is a wave piercing, stabilized, mono-hull. Hence a trimaran. Onto which is built in an:

a) Ultra light superstructure purposed designed to harvest energy from nature via b) and c) below,

b) Solar wings that track the sun and fold for storms, in concert with

c) A turbine generator on a mast that tracks wind conditions and furls for storms.

She has a theoretical displacement of: 30,000 - 45,000 kilograms (target) in 5083 alloy.

LINKS & REFERENCE https://www.schottel.de/en/portfolio/products/product-details/srt-schottel-rimthruster https://www.boatdesign.net/threads/how-many-lbs-of-thrust-is-equal-to-1-hp.24964/ https://www.radiosailingtechnology.com/index.php/hulls/estimating-the-hull-drag-of-an-iom-yacht-august-2014 http://solarnavigator.net/wave_drag_boat_design.htm http://solarnavigator.net/propellers.htm http://www.solarnavigator.net/hull_drag.htm https://forums.ybw.com/index.php?threads/working-out-hull-drag.272540/

|

|||

|

Please use our A-Z INDEX to navigate this site or return HOME

This website is Copyright © 2021 Jameson Hunter Ltd

|